Today, pumps are everywhere, from homes to swimming pools, farms to fuel depots. However, not all pumps are created equal, and different pumps have different applications. Each application can have unique challenges, which is why it is advisable to consider the technical characteristics of the application when choosing a pump.

It is good to know the parameters of the work, such as fluid flow rate, suction head, discharge head, the viscosity of the fluid, etc. Use this guide to choose the right pump for the job.

Know the fluid properties

When you shop for a pump at PumpBiz, the first thing a vendor will ask you is the type of fluid you intend to pump or the specific application. This is because liquids such as fuels and chemicals can corrode or damage a pump not built for the task. Therefore you should select a pump designed to handle the consistency and corrosiveness of the fluid you want to pump to avoid degradation or clogging due to slurry and debris.

What is your required flow rate?

This is a critical question when choosing a pump for a specific application. Flow rate equals the total volume by the time you want to move the fluid. For instance, a pump with a minimum flow rate of 500gallon per hour is ideal a 500gallon pond that requires total circulation every hour. The flow rate significantly influences your choice of pump size.

Consider the operating temperatures.

The worst thing you can do is choose a pump without considering the operating temperature, especially one for industrial purposes. If your pump needs to pump hot liquids, it is crucial to let the vendor know to advise you accordingly. Otherwise, you may have to return to the drawing board within no time. Although pumps can operate at a wide range of temperatures, you should ensure that the pump is rated for the maximum temperature of the liquid you intend to pump.

Know the vapor pressure

The pump you choose should be rated for your fluid’s specific vapor pressure to eliminate the risk of cavitation. Vapor pressure refers to the fluid’s force per unit area when converting from a liquid into vapor. This consideration is critical, especially when choosing an industrial pump.

Compare different types of pumps.

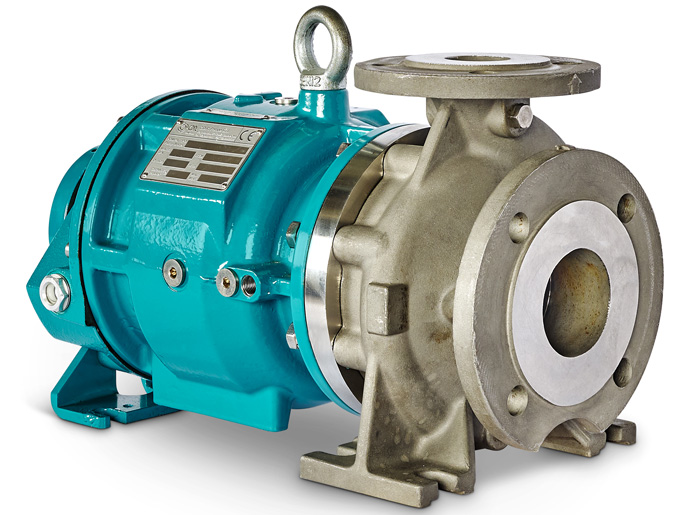

Over time, pumps have evolved in design and technology. When you understand the properties of the liquid you intend to pump, you can now compare different pump options such as:

- Centrifugal pumps: they pump all sorts of low viscosity fluids, especially those containing solid elements like wastewater.

- Diaphragm pumps help pump liquids with high viscosity like paints, syrups, and chemicals.

- Circulating pumps distribute liquid within the same system rather than moving it from one place to another. They are mostly used in water fonts and hot water systems.

- Chemical pumps are specifically used for developing, using, and disposing of chemicals.

- Fuel and oil transfer pumps move fuel and oil substances.

- Drum pumps suction out fluids from barrels, drums, and totes.

conclusion

Research extensively and buy your pump from a reputable vendor.